Grain Handling Systems: Monitoring & Control |

|

| Grain handling facilities are an integral part of producing important commodities such as corn, wheat, or soy. These facilities feature large silos, conveyer belts and augers, motors and fans, chutes and doors, and other heavy equipment. Critical measurements required to properly run a facility include temperature, humidity, bin level, equipment condition monitoring, and a variety of on/off or open/closed states. |

|

Traditionally, grain handling facilities were run manually, with perhaps a few level sensors to monitor inventory. An employee would need to be at the facility at all times to ensure it runs smoothly without any overfills, equipment failure, or safety violations. However, with new technology becoming evermore accessible, farmers are shifting to automation for better grain handling. |

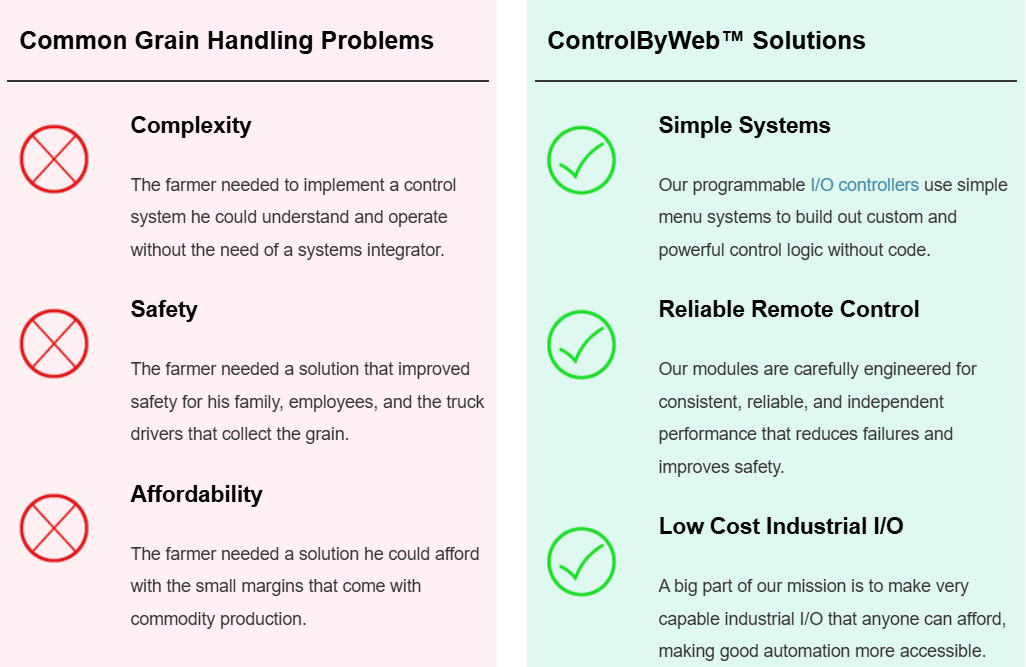

ControlByWeb IoT controllers are perfect for small and medium-sized automation projects such as these. We make control logic a breeze with affordable control modules that consistently perform for many years. |

. . |

|

Upgrade your grain handling facility with automated monitoring and control!

Discover how ControlByWeb’s IoT controllers can improve efficiency and safetyOur I/O solutions are capable of monitoring and controlling nearly anything. Your grain handling equipment and/or process might be a bit more unique. However, we monitor and control sensors and equipment in a variety of industries and applications. Rest assured, we can help you with your process.

Grain Equipment

What kind of grain handling equipment can I control and/or monitor with ControlByWeb?

Our I/O solutions are capable of monitoring and controlling nearly anything. Your grain handling equipment and/or process might be a bit more unique. However, we monitor and control sensors and equipment in a variety of industries and applications. Rest assured, we can help you with your process.

Our I/O solutions are capable of monitoring and controlling nearly anything. Your grain handling equipment and/or process might be a bit more unique. However, we monitor and control sensors and equipment in a variety of industries and applications. Rest assured, we can help you with your process.

Motor Monitoring

How do I monitor motor status and amperage?

When monitoring and controlling motors, its common to log the motor amperage. This is done with a current transducer connected to an analog input on one of our devices. You can also tell the run status of the motor and track run time via logging.

When monitoring and controlling motors, its common to log the motor amperage. This is done with a current transducer connected to an analog input on one of our devices. You can also tell the run status of the motor and track run time via logging.

Sensor Lifespan

How long do temperature and humidity sensors last?

Temperature sensors have a long service life of many years. Humidity sensors, however, are more sensitive to environmental contaminants which can coat the sensor and affect its accuracy and longevity. Exposure to condensation and/or organic compounds will shorten its life expectancy. A humidity sensor is a consumable product that depends heavily on the environment where it is installed. Periodic replacement of your humidity sensor will ensure accurate measurements.

All of our humidity sensors have a protective membrane to increase its life expectancy, while our humidity probe (X-DTHS-P) has a bronze filter for even more protection from contaminants.

Temperature sensors have a long service life of many years. Humidity sensors, however, are more sensitive to environmental contaminants which can coat the sensor and affect its accuracy and longevity. Exposure to condensation and/or organic compounds will shorten its life expectancy. A humidity sensor is a consumable product that depends heavily on the environment where it is installed. Periodic replacement of your humidity sensor will ensure accurate measurements.

All of our humidity sensors have a protective membrane to increase its life expectancy, while our humidity probe (X-DTHS-P) has a bronze filter for even more protection from contaminants.