Water Tower Temperature ControlMuch of our water supply system uses above-ground water supply tanks that are vulnerable to a number of environmental threats. One of them is cold weather. While it’s technically possible to put water supply tanks underground to keep it safer, doing so is incredibly expensive and requires massive civil engineering projects, many more pumps, and a lot more energy consumption. |

|

|

|

In reality, it’s easier to simply add heat and insulation to vulnerable points in our water supply as needed. A common point of concern in the system is the riser, a pipe that runs from ground level up to the bottom of the water supply tank. These pipes are small enough that they’re vulnerable to freezing rather quickly. |

|

Malcolm Jackson, the Business Development Manager for tank and maintenance supply company Utility Service Co., Inc., explains:

This is only one example of preventing water infrastructure from succumbing to the cold, and there are countless other industrial use cases for water temperature control; from food processing to data centers. Whether it’s meant for consumption or for processing, water management is incredibly important. |

|

|

Take control of your water tower temperature

Enhance the performance of your water tower system with ControlByWeb’s reliable temperature monitoring solutions. Schedule a consultation today to discover how our smart devices can help you optimize your operations, improve system efficiency, and ensure real-time data accessSeamlessly integrate temperature sensors. Connect a variety of temperature sensors with ControlByWeb devices for precise monitoring. Whether it’s analog, Modbus RS-485, or other sensor types, our devices are built to handle your water tower's unique requirements

Requirements

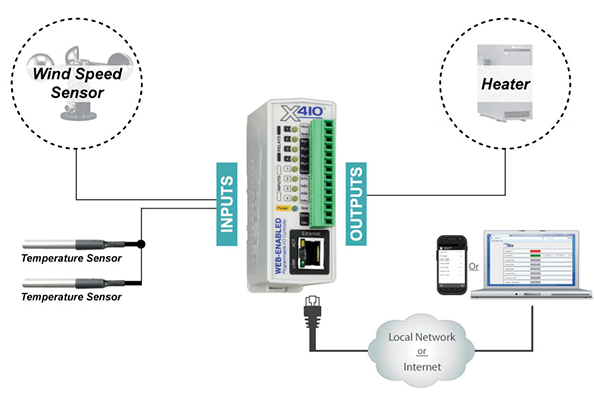

For a simple water tank temperature monitoring and control, similar to our customer above, 2 temperature sensors, one measuring the water riser and one measuring outside air, are sufficient and can be monitored with a single ControlByWeb I/O device. Our maximum number of temperature sensors on our X-410 I/O device is 16 – more than enough capacity.

Centralized Control

Data Logging

Yes. Many of our controllers support periodic logging intervals of sensor data, including temperature data. We store a log file on board which can be accessed via a web browser, sent as an email, or uploaded to an FTP server. Sensor data is also available via Modbus TCP/IP to interface with existing SCADA or other control systems.

Control Logic Programming

Our X-400 Series edge data controllers can be programmed using our intuitive, no-code Task Builder which is built into the devices. You can also write BASIC scripts for more advanced logic. The X-600M Expandable I/O Controller can be programmed using LUA

Weather Station Support

Many of our IoT controllers can monitor a variety of environmental sensors. Most control logic is based on individual sensors for maximum versatility. Our controllers have both analog and digital inputs to capture nearly any sensors data. Our 400 Series controllers have digital inputs with frequency and counting capabilities for specific types of weather sensors. For example, some wind sensors have a contact-closure frequency output that is based on the number of on/off pulses in a second. Rain gauges also use contact-closures to measure rainfall. The frequency and counting features on the 400 Series controllers accommodates these outputs.