The X-600M is a web-enabled multi-function module for control and monitoring via Internet or local network

Technology

ControlByWeb

Industry

Agriculture

Client

Industrial Ventilation IVI

Country

Idaho, USA

Goals

Maintain optimal conditions (temperature, humidity, CO2) to enhance shelf life and quality of root vegetables. Utilize industrial HVAC systems for precise control, accommodating various storage methods (bulk and crate) to balance speed and volume. Implement a control system for automated and manual monitoring, providing end-users with visibility and control over storage conditions.

Challenges

Address challenges associated with bulk and crate storage, balancing speed, & volume considerations. Mitigate the impact of low humidity on vegetable shrinkage & achieve precise monitoring to prevent weight loss. Develop a fully custom, simple, and flexible integration for control hardware to meet the unique needs of Industrial Ventilation, Inc. (IVI).

Solutions

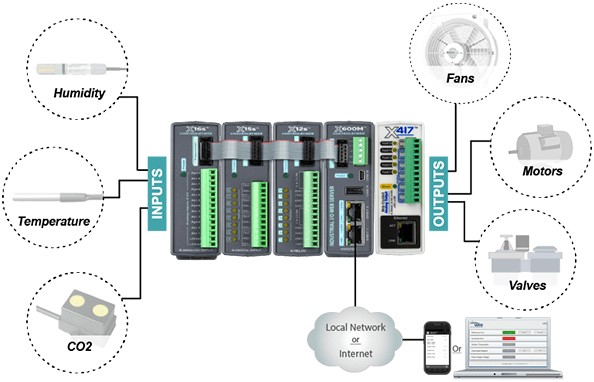

Implement features such as precise humidity and CO2 control, user-defined settings, and multiple timed runs to optimize storage conditions. Utilize X-600M as a master controller with various expansion cards (X-12s, X-15s, X-16s, X-417) for monitoring and control. Leverage the flexibility of ControlByWeb products for custom software integration, utilizing HTTP GET requests and JSON files for data exchange and achieving a wide variety of solutions.

Results

Achieved and maintained optimal temperature and humidity levels, preserving freshness, minimizing damage,& ensuring weight retention. Implemented the Imperium panel with ControlByWeb products, providing precise control and tools for successful storage management. Utilized ControlByWeb IIoT devices with industry-leading reliability, allowing for flexible integration with custom software while maintaining system reliability.

|

Growing and harvesting root vegetables takes a lot of money and effort. If stored incorrectly, the crop can be damaged, diminish in value, and even spoil. Thanks to advancements in environment monitoring and control, storage facilities have come a long way since the root cellar. Small-scale operations may include fans and an HVAC unit for basic temperature control and air movement. At an industrial level, facilities monitor and control temperature, humidity, airflow, CO2, and more with a variety of finely tuned equipment. |

Industrial Ventilation Inc. (IVI) designs and builds storage facility control systems and equipment to be used for root vegetable crops. Supporting their impressive system was difficult due to complex hardware integrations. That’s why they turned to ControlByWeb.When IVI created their next-generation product, they needed the right hardware to eliminate the problems from past systems—reliability, complexity, and a lack of flexible system architecture. Using our innovative and simplified control hardware, IVI improved reliability and dramatically simplified their control system integration.

|

|

|

ControlByWeb Products Used in Panels X-600M – A master controller capable of monitoring & controlling over 1,000 I/O |

System Features Monitor and control relative humidity and the CO2 with precision |

| Common Problems | Solutions |

| Failure rates - System failure can be catastrophic for the crop, leading to significant financial loss through damage or spoilage | Reliability- Our USA-made hardware is carefully engineered and expertly manufactured. We're known for consistent reliability |

| Rigidity- Environmental control systems often require custom solutions and retrofits. Cookie-cutter systems simply don't work | Flexibility - ControlByWeb programmable controllers network, install, and communicate easily in either a master or a node role |

| Complexity - Control hardware can be difficult to get working in unison, creating overly complex integration and resulting in failure | Simplicity - With multiple, well-understood ways to poll data from our devices, communication becomes simple and integration streamlined |