Technology

Matrikon

Industry

Food and Beverage

Client

TasteWell Foods Ltd

Country

Islamabad

Goals

Streamline production processes for enhanced efficiency and productivity. Enable real-time monitoring and control of production equipment for proactive quality management.

Challenges

Integration of diverse production equipment and control systems for optimized efficiency. Need for real-time data exchange and monitoring to minimize downtime and improve quality.

Solutions

Deployed Matrikon OPC for standardized communication between production equipment and control systems. Implemented OPC Data Manager for real-time data exchange and monitoring. Integrated Matrikon OPC with MES systems for enhanced production management.

Results

Optimized production processes with streamlined automation. Improved product quality and reduced waste through real-time monitoring and control. Enhanced production management for proactive decision-making.

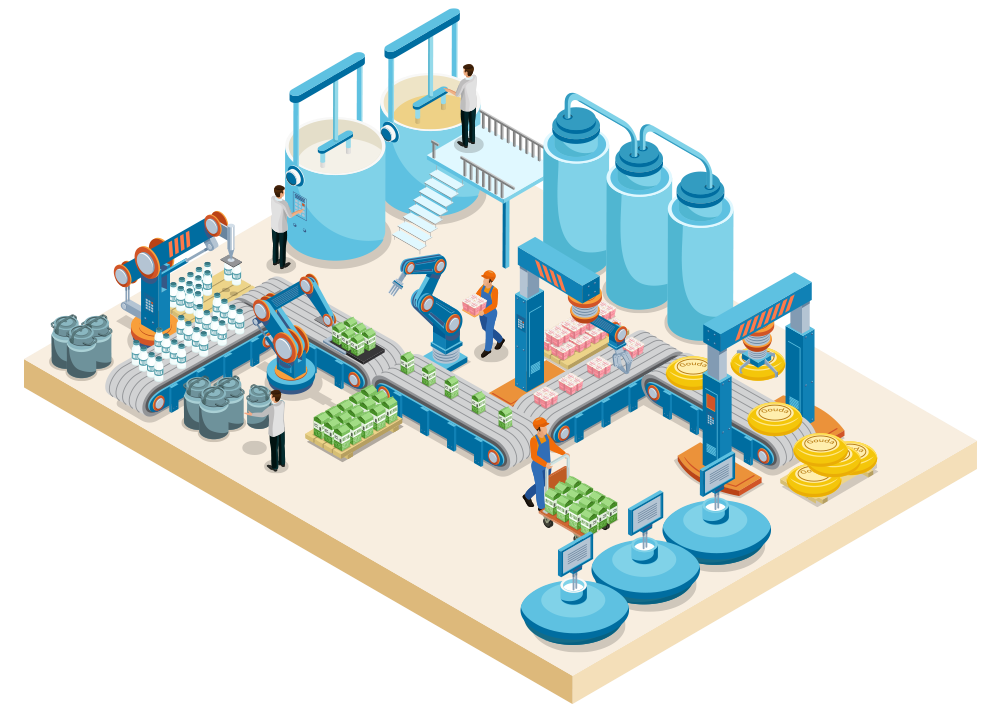

TasteWell Foods Ltd., a leading food and beverage manufacturer

Aimed to optimize its production processes through seamless integration and real-time monitoring. Matrikon OPC emerged as the solution to integrate diverse production equipment and control systems, enabling proactive quality management and production optimization. In the fast-paced world of food and beverage production, efficiency and quality are paramount. TasteWell Foods Ltd. recognized the importance of optimizing its production processes to meet consumer demands and maintain high-quality standards. With Matrikon OPC, TasteWell embarked on a journey towards enhanced efficiency and quality

At the core of this transformation lies Matrikon OPC, a versatile solution designed to facilitate standardized communication and real-time data exchange between diverse production equipment and control systems. By deploying Matrikon OPC, TasteWell achieved seamless integration of its production processes, paving the way for enhanced efficiency and quality. Imagine a scenario where production lines operate with precision, delivering high-quality products while minimizing waste and downtime. Matrikon OPC's cutting-edge technology made this vision a reality for TasteWell, enabling the company to improve product quality, reduce waste, and enhance overall production efficiency.

Matrikon OPC not only facilitated seamless integration

But also provided enhanced production management capabilities. By integrating with MES systems, TasteWell gained the ability to make proactive decisions based on real-time data, further optimizing its production processes and ensuring consistent quality. In an industry where consumer demands are ever-changing, Matrikon OPC stands out as the trusted partner for food and beverage manufacturers seeking to optimize their operations. Embrace the future of food and beverage production with Matrikon OPC, where seamless integration and proactive quality management drive success.

|

|