The X-420™ offers programmable digital I/O, configurable as input or output

Technology

ControlByWeb

Industry

Water Treatment

Client

Ohio Valley

Country

Ohio, USA

Goals

Achieve easy remote access to process data with on-board logic that remains secure & unaffected by external factors like network connectivity. Provide scalability for larger water and wastewater projects while maintaining simplicity for smaller installations. Ensure reliability and affordability in control systems design for water and wastewater projects in the Ohio River valley.

Challenges

Initial consideration of designing custom control boards for specific project requirements. Need for efficient remote monitoring of lift stations, well levels, pump status, and fault conditions. Address the challenge of accommodating both smaller and larger projects with varying control system needs.

Solutions

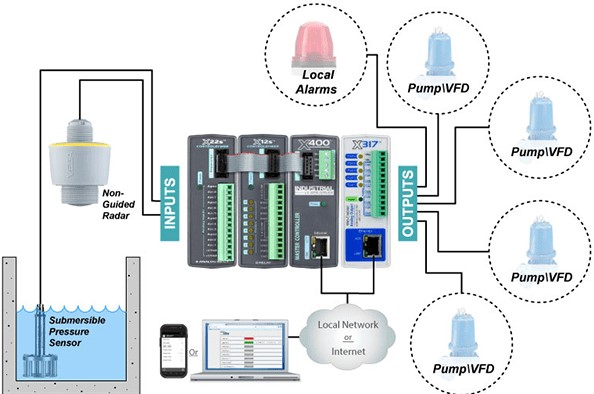

Utilize ControlByWeb's X-420 with programmable digital and analog inputs for flexible configuration. Integration of a 3" HMI screen with Ethernet input for local display and programming, enhancing monitoring and programming capabilities. The use of multiple X-420s or the X-400 with expandable I/O modules to meet increased I/O requirements of larger lift stations. Implement the X-417 for lift stations with Variable Frequency Drives (VFDs), mirroring analog signals from level transducers to VFD units.

Results

Adoption of ControlByWeb programmable I/O controllers, specifically the X-420 and 400-Series products. Successful implementation of features such as pump start/stop signals, pump alternating logic, and email/text alarm functionality for lift station management. Replacement of several components in a pump control panel by the X-420, contributing to operational profitability and cost savings for Ohio Valley Control Systems.

|

How Lift Stations Work They are known as lift stations because they pump the wastewater up and allow gravity to take over as it flows toward the next lift station. Mountainous or hilly areas will have fewer lift stations because they have more slope to work with. But flat areas need more lift stations to engineer a slope where it doesn't naturally exist. Lift stations consist of a well where wastewater collects, Pumps that move the water once the well is full enough, and Controllers that monitor the well and send signals to the pumps, operators, and a central control system. |

| Features Expandable I/O |

|

| Common Problems | Solutions |

| Expensive monitoring - Access to additional monitoring such as pump status and fault condition monitoring requires additional I/O and can dramatically increase the cost of the monitoring solution | Affordable functionality - Industrial-grade, inexpensive and flexible I/O empowers control systems engineers and municipalities to monitor more, like pump status and fault condition, for the allotted budget |

| Insufficient alarms - On-site alarms are insufficient to notify operators of emergency conditions, and remote critical alarms often leave out helpful maintenance notifications | Text and email alarms - Text and email alarms can be triggered easily in our built-in setup pages for any parameter you are monitoring, making it easy to communicate with your operators in real time |

| Lack of scalability - Lift stations vary wildly in their complexity, modernity, and available budget. However, industry standard control systems don't scale up or down easily | Expandable I/O - Easily configure a solution that matches your needs and your budget. Whether you're working with simple float switches or a VFD driven quadplex pump station |