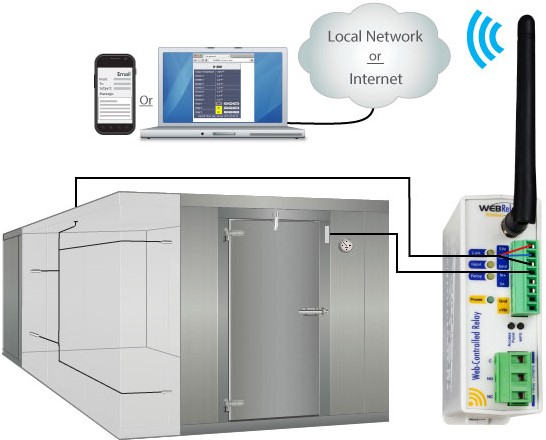

The X-600M is a web-enabled multi-function module for control and monitoring via Internet or local network

Technology

ControlByWeb

Industry

Hospitality

Client

Meadowbrook Restaurant

Country

Hanson, Massachusetts, USA

Goals

Create a safe and efficient workplace for restaurant staff. Streamline the management of multiple restaurants for faster and easier operations. Implement automation to enhance overall facility functionality.

Challenges

Initial difficulty with false temperature alarms, resulting in significant financial loss. Need to monitor and maintain the health of walk-in freezers, refrigerators, and other critical equipment. Preventing human errors in kitchen equipment operation to avoid dangerous situations.

Solutions

Implement ControlByWeb controllers, specifically the X-600M and X-400, for temperature monitoring and broader facility automation. Establish customized parameters and alerts to eliminate false alarms and enhance system responsiveness. Utilize the Task Builder and ControlByWeb Cloud compatibility for improved capabilities.

Results

Successful implementation of the X-600M for temperature monitoring, with logic to ignore non-critical events. Improved monitoring of cooler health, distinguishing between normal fluctuations and potential equipment failures. Automatic equipment shutoff and lock control to prevent human errors and enhance safety.

|

Joe Sharp is the Area Facilities Manager for Meadowbrook Restaurant Co.He's in charge of every aspect of the companies' buildings and making sure their equipment is fully functional. He does it all with the help of ControlByWeb expandable I/O controllers. Sharp has undertaken the task of automating his facilities as much as he can.His first task was to monitor walk-in freezers and refrigerators. Initially, he installed a competitor's temperature monitoring product. However, trouble arose when they received so many false temperature alarms that his staff began to ignore them. Eventually, they had a real equipment failure that went ignored, causing them to lose their inventory in a freezer that cost them more than $10,000. |

| Temperature Monitoring |

The mission quickly became to find a temperature monitoring system that had enough logic to ignore defrost cycles, typical door openings, etc. He found his answer in the X-600M from ControlByWeb. He is now able to monitor multiple coolers, log typical temperature fluctuations from normal operation, program alarm logic that only sounds for real problems, and add in a variety of building automation for safety and preventative maintenance.

| Cooler Health |

As a former refrigeration technician, Sharp simply taped temperature sensors to his coolant lines on the roof using the same X-600M to monitor his freezer/refrigerator performance. Now he knows if his coolers need maintenance a lot sooner, and he can distinguish between a door left open on a walk-in and equipment failure. Similarly, he runs his building HVAC through his X-600M, giving himself a remotely accessible thermostat.

| Automatic Equipment Shutoff & Lock Control |

To prevent human error from causing a dangerous situation, Sharp turned to the kitchen equipment.

He uses the same X-600M to automatically turn on and shut off all his hot cooking equipment each morning and every night respectively. He doesn't have to worry about a mistake causing a building fire. Likewise, the restaurant doors automatically lock & unlock at preset times. If his system doesn't perform as expected, he knows about it while he can still fix it quickly remotely accessible thermostat.

Complete Building AutomationSharp is looking for more ways he can use ControlByWeb controllers to automate his restaurants. Some of the things he's already automated include: |

|

| Common Problems | Solutions |

| Temperature monitoring and record keeping - Monitoring temperature manually is time consuming and can result in record keeping failures or errors. Lapses in monitoring is common and equipment problems while your staff is away can result in expensive losses | SMART COOLER MONITORING & DATA LOGGING - Automated walk-in cooler monitoring and temperature data logging means you can access reports whenever you need to, and are always immediately alerted to problems with your equipment before it's too late |

| Human error - Tired kitchen staff work hard during long nights. They can easily forget to lock the doors at night, shutdown a fryer, or miss the morning start up. Human error can be common, dangerous, and very costly | AUTOMATED STARTUP, SHUTDOWN, & LOCKING - Our affordable and reliable 400-Series controllers feature no-code programming with Task Builder and scheduling so you can easily automate door locking, the start-up and shutdown of cooking equipment, and nearly anything else |

| Alarm overload - Most monitoring solutions don't offer smart alarms without upgrading to more expensive packages. Slight temperature fluctuations can result in too many alerts which can cause staff to ignore them altogether | SMART ALARM LOGIC - Our controllers are built with on-board logic powerful enough to create intelligent alarms without code. It's easy to eliminate useless notifications so staff are only alerted to real problems |