Technology

Aveva

Industry

Oil and Gas

Client

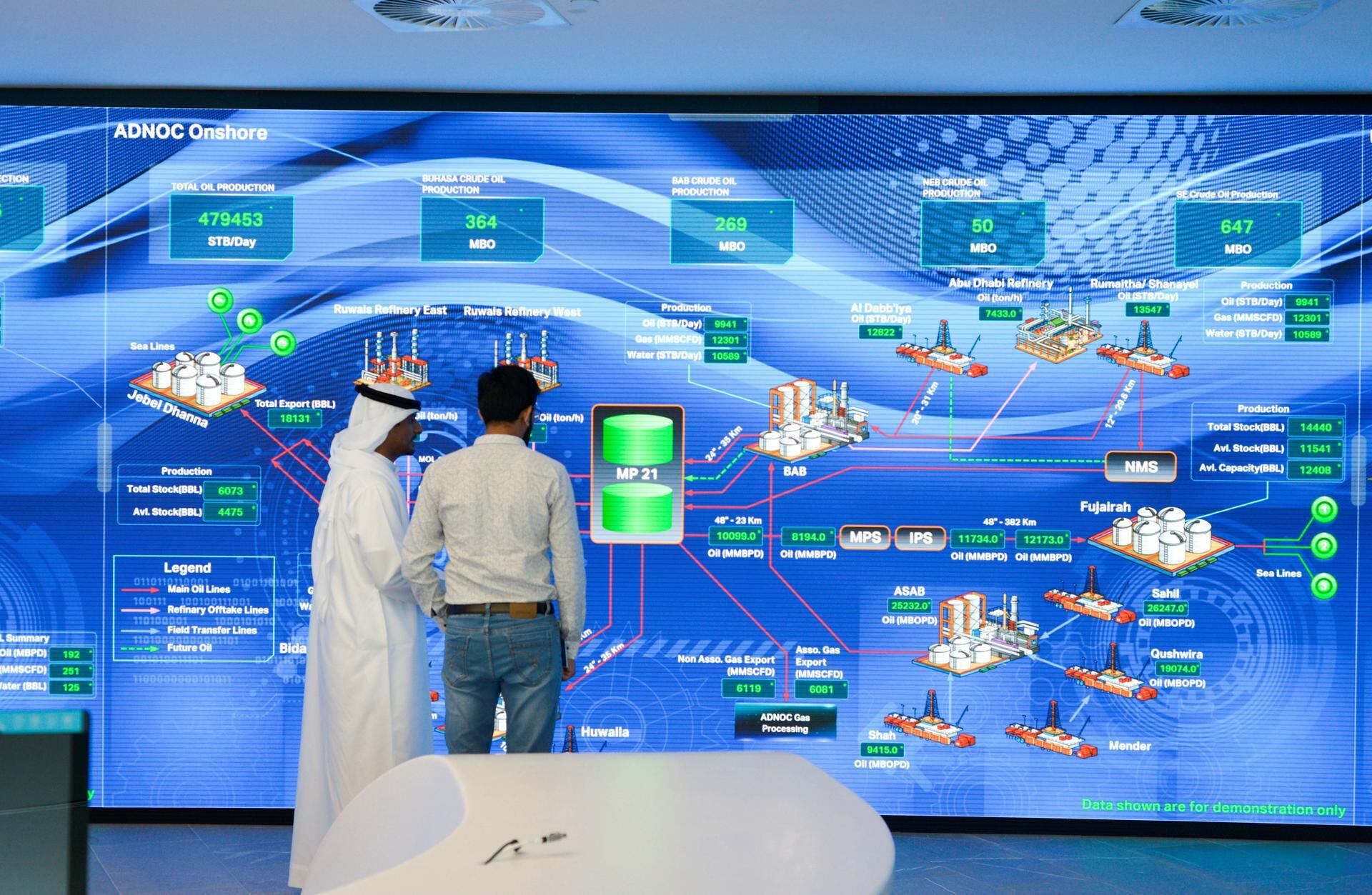

ADNOC

Country

UAE

Goals

Remotely gathered and analyzed RTU requirements for Clusters #43 and #47. Configure 522 PI tags on the existing FDIS system. Deploy 20 ProcessBook graphics using approved templates remotely. Conduct remote Site Acceptance Testing and clear punch list items.

Challenges

Executing configuration and deployment activities mostly remotely. Integrated changes with OPC and control systems. Coordinating communication between multiple stakeholders across locations. Maintaining high standards of graphics quality and system documentation.

Solutions

Led remote workshops for requirements and design. Configured PI tags and deployed graphics using consistent templates remotely. Conducted remote SAT with client participation and punch list tracking. Delivered comprehensive documentation supporting project transparency.

Results

Completed remote ICSS/SCADA upgrades for two ADNOC clusters. Improved operational monitoring with 500+ PI tags and 20 graphics. Completed SAT and punch list remotely with no delays. Provided thorough documentation for future system support and upgrades.

|

ADNOC ICSSSCADA ModificationPackage-2 for RTU's at Cluster #43 & 47 |

The scope involved gathering detailed requirements remotely, designing the system architecture, and configuring over 500 PI tags on the existing FDIS system. EMI also deployed 20 ProcessBook graphics remotely using standardized templates to ensure consistent visualization aligned with ADNOC standards. Comprehensive Site Acceptance Testing (SAT) was performed remotely, with punch list items addressed promptly to ensure system readiness and client satisfaction.

This remote execution demanded tight coordination between EMI, ADNOC, and Schneider Electric teams, leveraging digital tools and clear communication to maintain project quality and timelines. The delivery included detailed documentation such as Functional Design Specifications, SAT procedures, and method statements, ensuring transparency and support for future system maintenance.